A disperser mixer can dissolve, disperse, mix and emulsify liquid and liquid material, powder and liquid with different viscosity through the high-speed rotation of the dispersion plate.

There are two types of dispersing system working in users'factory.

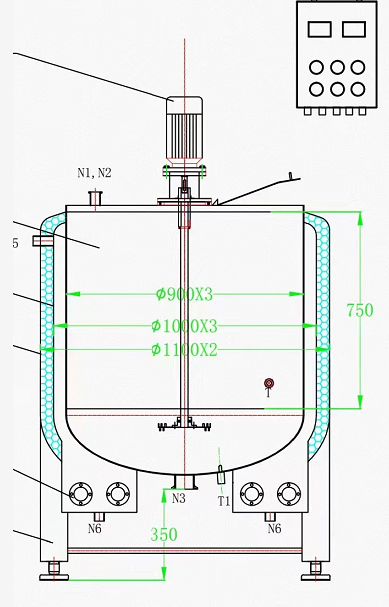

One type is installing a disperser mixer into a bucket, a tank/vessel

The other type is the disperser mixer with a moveable frame, operators can move the disperser mixer from one to another vessel easily and quickly.

The dispersing system be used to produce emulsions of two immiscible liquids or dispersions of solid particles in a liquid medium.

The mixers generally operate on the rotor/stator principle and apply a high shear force on the suspended particles to break them down. The choice of a dispersion mixer depends on the physical state of the material being dispersed, the continuous or batch nature of the process, desired particle size, and the viscosity of the mixture. Dispersion mixers are widely used in the food industry for the dispersion of solid ingredients in oil or water and in the coatings industry for the dispersion of pigments.

Feature of Shanghai You Can Disperser mixer

The surface of the high-speed dispersing machine is specially treated, and its appearance is novel and beautiful. With its stable performance and mature technology, it is a widely used production equipment.

1. Drive motor: Siemens / ABB / Explosion-proof and other options

2. Motor power: 0.75KW-110KW

3. Voltage: 380V / 415V / 50Hz / 60Hz

4. Speed regulation mode: frequency converter speed regulation / electronic speed regulation / PLC system

5. Speed range: 0 ~ 1000/0 ~ 1450/0 ~ 2900RPM

6. Processing range: 20L-10 cubic meters per batch

7. Sealing type: single end face / double end face mechanical seal, a variety of seal types can be selected to effectively prevent materials from being contaminated

8. Working type: high-speed shearing and paddle dispersion, strong mixing, high-speed dispersion, effective mixing of suspension and solid-liquid mixture, slurry, etc.

9. Body Material: SUS304 / SUS 316L/2205 / 2507 and other special materials.

10. Bracket material: stainless steel (It can fully comply with GMP standards)

11.Electrical control: ordinary switch lifting and stirring dispersion control system, PLC control system

12. Auxiliary equipment: pneumatic lifting system, automatic lifting system, manual lifting device, bucket holding device, bucket clamping device, etc.

13. Auxiliary accessories: pulling cylinder, reaction chick, vacuuming, pressure resistance, heating, cooling, temperature control device, etc.