Shampoos are a mixture of surfactants, conditioning agents and many other ingredients in an aqueous base. In addition to basic shampoos which simply clean the hair, there are products designed for specific hair types; “2-in-1” shampoos and conditioners; products which offer properties such as treatment of dandruff; UV protection; some degree of coloring (although most hair colorants are based on conditioners rather than shampoos); and “medicated” products.

The video below shows how to dilute a key ingredient in shampoos:

A typical manufacturing process would be as follows:

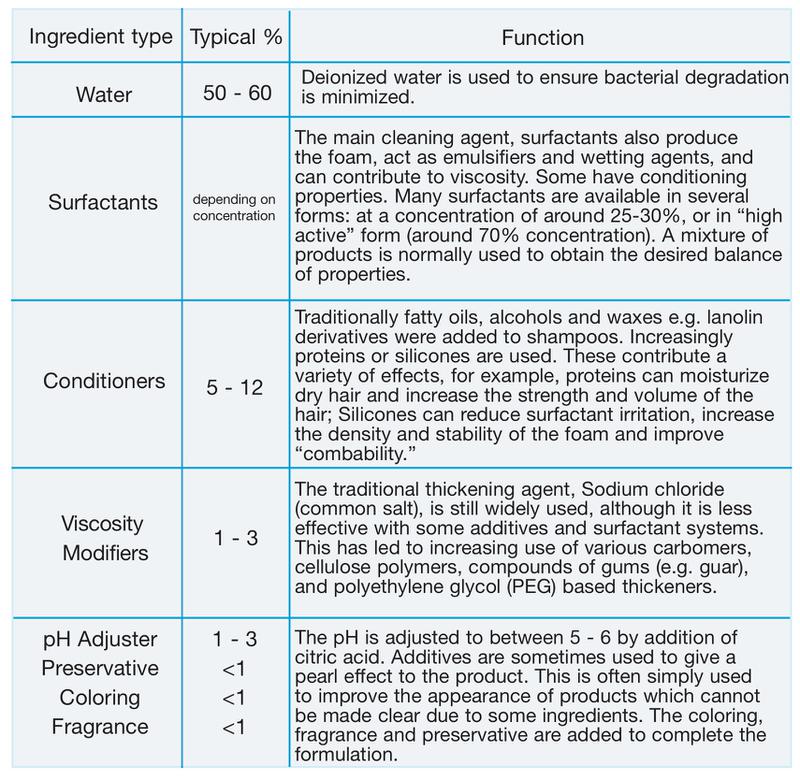

Formulations vary widely, however, the range of ingredients used can be summarized in the following table: