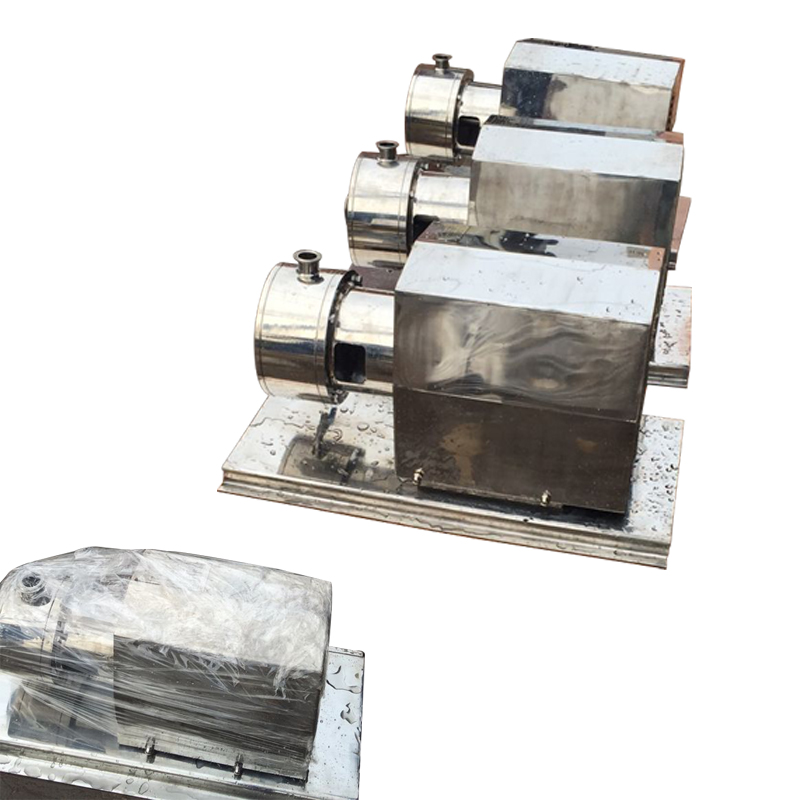

In-Line Mixer

High Shear In-Line Mixers has similar work theory with high shear batch emulsifier, which the rotor and stator work together to generate strong shearing power during speedy running to realize mixing, smashing and emulsion. Inline mixer could also be fixed on pipeline to do continuous work. The standard components are pump chamber, rotor and stator.

Inline mixer is applied to emulsify and disperse kinds of liquids continuously, transmits low viscosity material and mix powder and liquid.

Working Principle

Three sets of stators and rotors are equipped in working cavity. Driving shaft in working cavity is an arm, electrical motor and the shaft in bearing cabinet can be connected by spring coupling to improve the operation quality of driving shaft. Seal form can be selected in different conditions. It is fit for middle-large scale on-line continuous production or circulated treatment production process.

Principle Of Dynamics 1. Medium sucked in by strong axial suction force. 2. Single phase liquid, multi-phase liquid or suspended particles are pumped in though single-stage, double-stage or three-stage rotor and stators. 3. No matter what medium property is, pump will evenly shear all the liquid with high-intensity and controllable force. 4. Shearing rate is constant, different sizes depends on gear of rotor and stator and speed of rotor.

| In-Line Mixer High Shear Emulsion Pump Homogenizer Pump Technical Parameter | |||||||

| Type | Power (KW) |

Voltage | Rev (RPM) | Flow Rate Water (M3/h) | Outlet Pressure (MPa) | Material customized | |

| SRH-80 | 1.5 |

380V/220 V/440 V /480 V

Customized electricity system | 2900 | 0-1.5 | ≤0.2 | SS304 | SS316 |

| SRH-100 | 2.2 | 2900 | 0-3 | ≤0.2 | SS304 | SS316 | |

| SRH-130 | 4 | 2900 | 0-4 | ≤0.2 | SS304 | SS316 | |

| SRH-140 | 5.5 | 2900 | 0-5 | ≤0.2 | SS304 | SS316 | |

| SRH-165 | 7.5 | 2900 | 0-8 | ≤0.2 | SS304 | SS316 | |

| SRH-180 | 11 | 2900 | 0-12 | ≤0.2 | SS304 | SS316 | |

| SRH-185 | 15 | 2900 | 0-18 | ≤0.2 | SS304 | SS316 | |

|

| 18.5 |

|

|

| SS304 | SS316 | |

| SRH-200 | 22 | 2900 | 0-25 | ≤0.2 | SS304 | SS316 | |

| SRH-210 | 30 | 2900 | 0-35 | ≤0.2 | SS304 | SS316 | |

| SRH-230 | 45 | 2900 | 0-50 | ≤0.2 | SS304 | SS316 | |

| SRH-245 | 55 | 2900 | 0-75 | ≤0.2 | SS304 | SS316 | |

| SRH-260 | 75 | 2900 | 0-90 | ≤0.2 | SS304 | SS316 | |

| SRH-275 | 90 | 2900 | 0-110 | ≤0.2 | SS304 | SS316 | |

| SRH-280 | 132 | 2900 | 0-130 | ≤0.2 | SS304 | SS316 | |