Batch Mixers

Silverson High Shear Batch Mixers A Silverson high shear batch mixer doesn't simply mix; it emulsifies, homogenizes, solubilizes, suspends, disperses and disintegrates solids. Each mixer, with its precision-engineered Silverson rotor/stator workhead, far outperforms conventional mixers, cutting processing times by up to 90%, improving quality, product consistency and process efficiency

A Silverson high shear batch mixer doesn't simply mix; it emulsifies, homogenizes, solubilizes, suspends, disperses and disintegrates solids. Each mixer, with its precision-engineered Silverson rotor/stator workhead, far outperforms conventional mixers, cutting processing times by up to 90%, improving quality, product consistency and process efficiency.

Silverson High Shear Batch Mixers will:

- Process from 1 to 8000 gallons

- Customized to be equiped with stainless steel tanks, stainless steel lifter

- Eliminate agglomerates and fish eyes

- Create stable emulsions and suspensions

- Reduce particle size

- Rapidly dissolve solids

- Accelerate reactions

How it Works

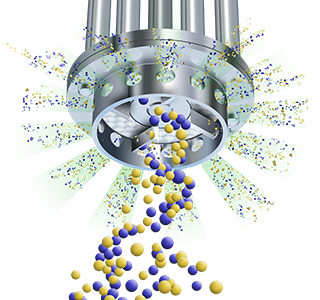

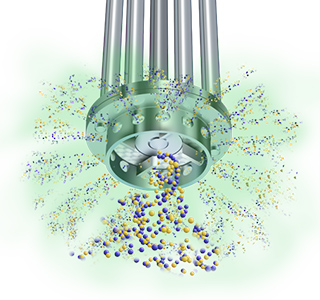

The advantages of Silverson’s high shear rotor/stator batch mixer over simple conventional stirrers or agitators stem from the multistage mixing/shearing action as materials are drawn through the specially designed Silverson workhead - the heart of every machine.

Stage 1

The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials upwards from the bottom of the vessel and into the center of the workhead.

Stage 2

Centrifugal force then drives materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator and circulated into the main body of the mix.

Stage 4

The materials expelled from the head are projected radially at high speed towards the sides of the mixing vessel. At the same time, fresh material is continually drawn into the workhead maintaining the mixing cycle. The effect of the horizontal (radial) expulsion and suction into the head is to set up a circulation pattern that minimizes aeration caused by the disturbance of the liquid’s surface